Highlights include 8.7m @ 1.46g/t PGM+Au, 0.46% Ni (Including 2.0m @ 4.11g/t PGM+Au, 1.68% Ni),

And: 4.9m @ 1.13g/t PGM+Au, 0.56% Ni (Including 0.9m @ 3.06g/t PGM+Au, 2.05% Ni)

VANCOUVER, April 04, 2022 – Bravo Mining Corp. (TSX.V: BRVO, OTCQX: BRVMF), (“Bravo” or the “Company”) announced that it has received assay results from five diamond drill holes (“DDH”) in the North Sector, drilled along strike from the previously announced magmatic nickel (± copper) sulphide intercepts drilled as part of the Phase 1 program (see news releases dated February 14th, 2023 and August 16th, 2022), at its 100% owned Luanga palladium + platinum + rhodium + gold + nickel project (“Luanga” or “Luanga PGM+Au+Ni Project”), located in the Carajás Mineral Province, state of Pará, Brazil.

“With infill drilling alone continuing to intercept magmatic nickel sulphides at depth, the Company is accelerating its plans for exploration with the commission of a detailed airborne Electromagnetic (“EM”) survey over the entire Luanga project area (7.810ha)” said Luis Azevedo, Chairman and CEO of Bravo. “While our understanding of the distribution and controls on magmatic nickel (± copper) sulphide mineralization is still in its early stages, we continue to see patterns and evidence that suggest potential at depth and in the ultramafic footwall sequence, and perhaps these might lead towards a common more central location below the Luanga intrusion.Fast-tracking a comprehensive geophysics program could unlock the potential below Luanga, and greatly accelerate the Phase 2 exploration program in 2023,” he said.

Highlights Include:

- Infill drilling continues to intercept magmatic nickel sulphides at depth at Luanga, further reinforcing the need to accelerate focused nickel exploration below the known PGM+Au mineralization at Luanga.

- Drilling in the North Sector of Luanga has intercepted the continuation of magmatic nickel sulphides, below the depth of existing historical drilling.

- A significant detailed geophysical program is being commissioned to accelerate the ongoing Phase 2 program.

- A detailed HeliTEM (Helicopter airborne EM) survey over the entire Luanga project is the key component of the geophysics program.

- Detailed gravity and ground magnetic surveys have also commenced, prioritizing prospective magmatic nickel sulphide targets within favourable geology, and potential feeder zone target(s).

| HOLE-ID | From (m) |

To (m) |

Thickness (m) |

Pd (g/t) |

Pt (g/t) |

Rh (g/t) |

Au (g/t) |

PGM + Au (g/t) |

Ni* (% Sulphide) |

TYPE |

|---|---|---|---|---|---|---|---|---|---|---|

| DDH22LU080 | 186.6 | 195.3 | 8.7 | 0.92 | 0.47 | 0.06 | 0.01 | 1.46 | 0.46 | FR |

| Including | 186.5 | 188.5 | 2.0 | 2.89 | 1.03 | 0.16 | 0.03 | 4.11 | 1.68 | FR |

| And | 203.3 | 208.2 | 4.9 | 0.56 | 0.50 | 0.06 | 0.01 | 1.13 | 0.56 | FR |

| Including | 205.4 | 206.3 | 0.9 | 1.38 | 1.56 | 0.12 | 0.01 | 3.06 | 2.05 | FR |

| DDH22LU087 | 20.3 | 52.9 | 32.6 | 1.71 | 1.07 | 0.15 | 0.06 | 2.99 | NA | Ox/FR |

| Including | 41.9 | 52.9 | 11.0 | 2.62 | 1.36 | 0.18 | 0.08 | 4.24 | 0.27 | FR |

| DDH22LU088 | 156.8 | 161.5 | 4.7 | 1.45 | 0.51 | 0.01 | 0.01 | 1.99 | 0.83 | FR |

Notes:

- All ‘From’, ‘To’ depths, and ‘Thicknesses’ are downhole.

- All intercepts were in fresh rock.

- Given the orientation of the hole and the mineralization, the intercepts are estimated to be 85% to 100% of true thickness.

- * Bravo’s nickel grades are sulphide nickel, and do not include non-recoverable silicate nickel, unlike historic total nickel assays.

Magmatic Nickel Exploration Program

Given the increasing number of magmatic nickel sulphide intercepts at depth in the infill drilling program, and the recent commencement of Phase 2 extensional drilling below this mineralization, Bravo has elected to accelerate its exploration program targeting magmatic nickel (± copper) sulphides at Luanga.

The Company has engaged a geophysical contractor to complete a HeliTEM survey over the entire Luanga project. The EM survey is planned at a detailed line spacing of 150m and is expected to be carried out in Q2, 2023.

A ground magnetic survey is underway, with 35 line/km completed to date utilizing Bravo’s own equipment. A detailed gravity survey has commenced using the Company’s new CG-6 gravity meter and base station (Figure 1). These surveys prioritize prospective nickel stratigraphy and potential feeder zone target/s.

Figure 1: Gravity Base Station at the Luanga Office (Left). Geophysics Technician at work with Gravity Meter (Right).

North Sector Magmatic Nickel Sulphides in Infill Drilling

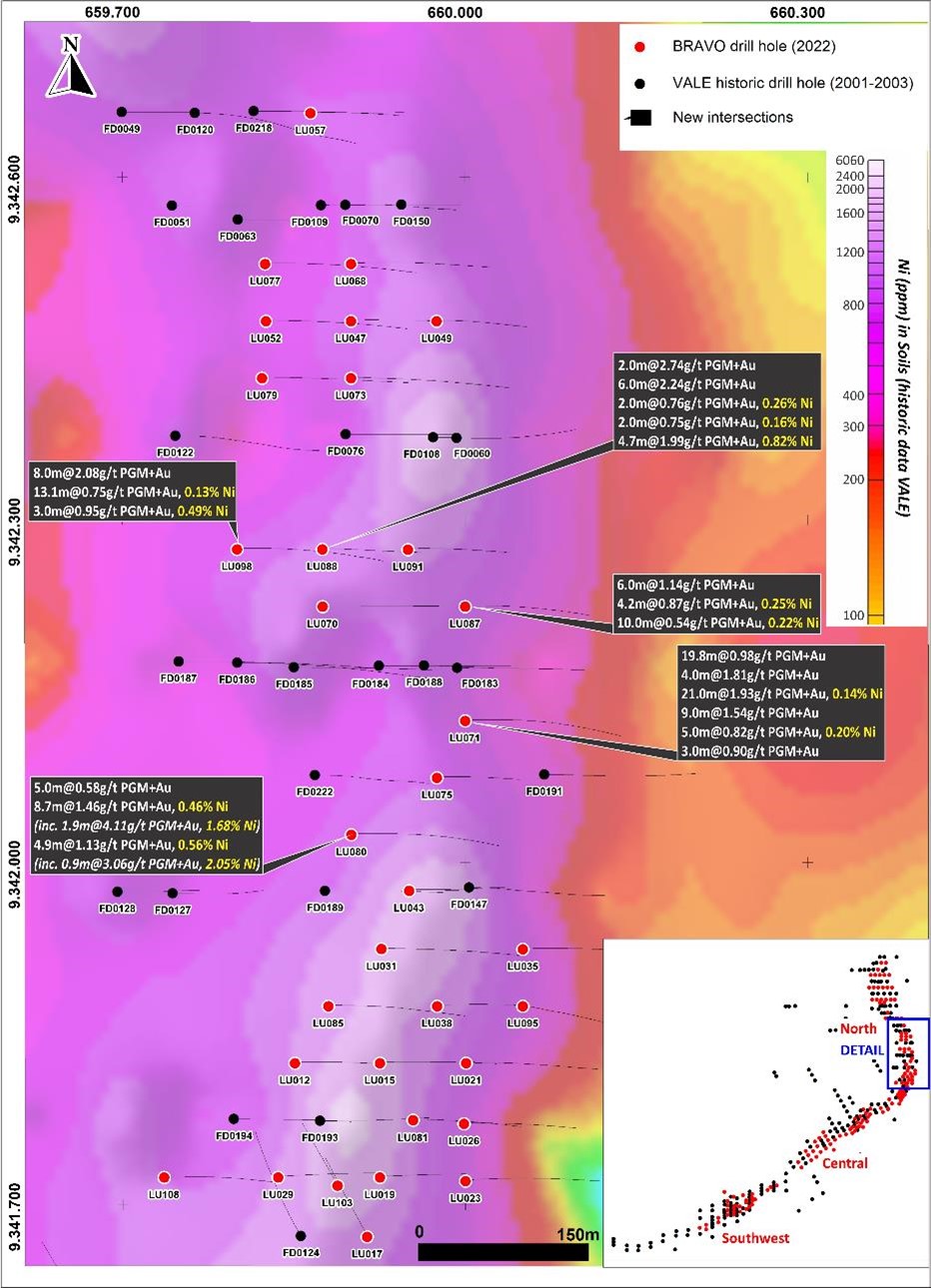

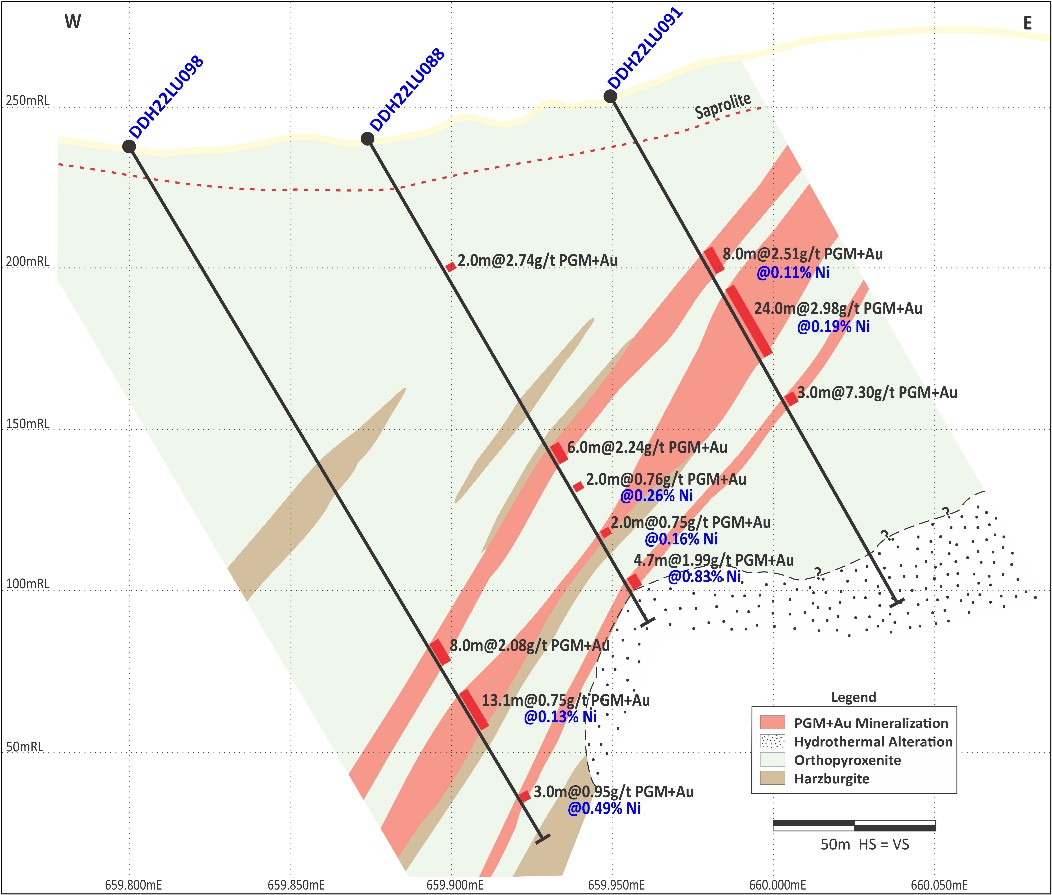

Infill drilling in the North Sector (Figure 2) continues to intercept magmatic nickel sulphides at depth (Section - Figure 4). Some infill drilling by Bravo has been deeper than historical drilling on nearby sections, perhaps explaining the absence of observed nickel sulphides in historical drilling.

Figure 3 shows the location of drill results in this news release, demonstrating that higher-grade magmatic nickel sulphides are vectoring to the south, towards the center of the intrusion, whilst passing under the depth extent of the shallower drilling on historical drill sections.

The Phase 2 program has commenced, with 21,500 meters of drilling planned, focused on extensional drilling to depth (below the known mineralization) and exploration of new targets. The extensional drilling seeks to follow the Luanga PGM+Au deposit down dip while, at the same time, extending holes to depths sufficient to test the interface between the PGM host sequence and the ultramafic footwall sequence. The accelerated geophysical program aims to generate magmatic nickel sulphide exploration targets and examine the entire Luanga project area, including outside the mineralized footprint identified to date.

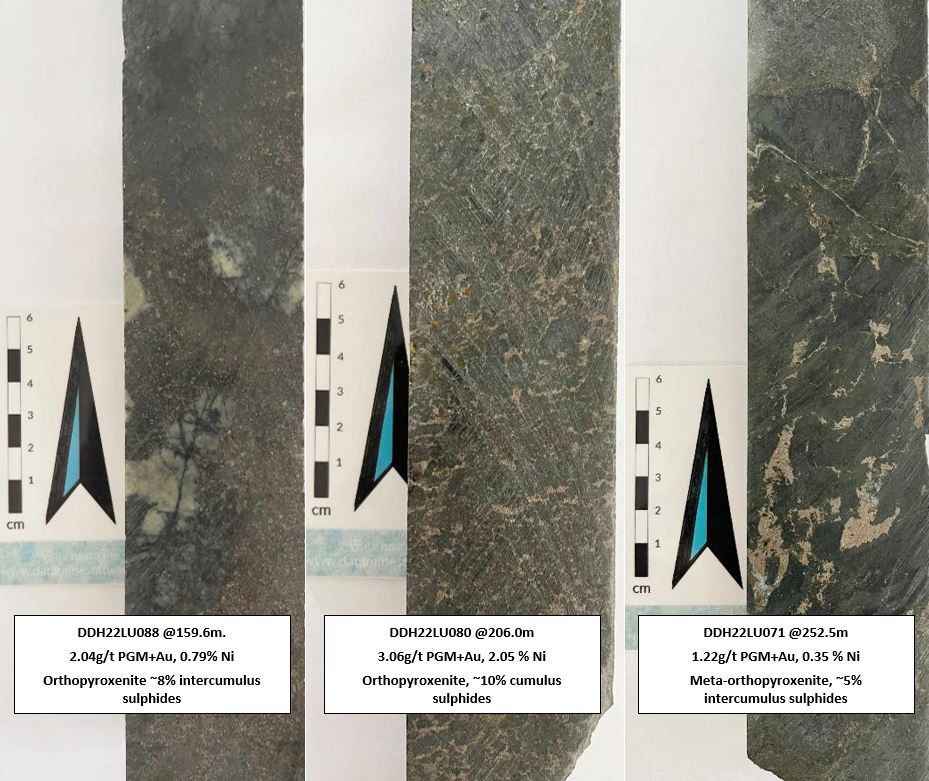

Figure 2: Core photos from North Sector (DDH22LU088, 080 and 071), nickel ± copper sulphide mineralization.

DDH22LU088 and DDH22LU098 shown in the section below (Figure 4), encountered magmatic nickel sulphides close to the bottom of the drill holes, deeper than tested by nearby historical drilling. Current exploration targeting thus recognizes the magmatic nickel sulphide potential at depth, closer to the ultramafic footwall sequence and within the ultramafic footwall sequence, and vectoring towards the center of the Luanga intrusion which ideally should be closer to a feeder zone location. Similarly magmatic nickel sulphides encountered in the Central Sector also appear to vector towards the center of the Luanga intrusion, which aligns with the Company’s geological model for Luanga.

Figure 3: North Sector – New magmatic nickel sulphide intercepts in infill drilling, shown over historic Ni-in-soil geochemistry.

Figure 4: North Sector cross section showing the increase in magmatic nickel sulphides at depth (open at depth).

Luanga Drill Program Progress

A total of 165 drill holes (30 in 2023) have been completed by Bravo to date, for 28,674 metres, including all 8 planned twin holes and all 8 metallurgical holes (not for routine assaying).

Results have been reported for 117 Bravo drill holes to date. Excluding the 8 metallurgical holes, results for40 Bravo drill holes are currently outstanding.

Luanga’s maiden NI 43-101 MRE is on-track for H2/2023.

Complete Table of Recent Intercepts

| HOLE-ID | From (m) |

To (m) |

Thickness (m) |

Pd (g/t) |

Pt (g/t) |

Rh (g/t) |

Au (g/t) |

PGM + Au (g/t) |

Ni* (% Sulphide) |

TYPE |

|---|---|---|---|---|---|---|---|---|---|---|

| DDH22LU071 | 0.0 | 19.8 | 19.8 | 0.48 | 0.33 | 0.06 | 0.11 | 0.98 | NA | Ox |

| And | 86.7 | 90.7 | 4.0 | 0.87 | 0.77 | 0.14 | 0.04 | 1.81 | 0.08 | FR |

| And | 94.7 | 115.7 | 21.0 | 0.78 | 0.89 | 0.11 | 0.15 | 1.93 | 0.14 | FR |

| And | 119.7 | 128.7 | 9.0 | 0.70 | 0.69 | 0.09 | 0.05 | 1.54 | 0.06 | FR |

| And | 249.6 | 254.6 | 5.0 | 0.61 | 0.19 | 0.01 | 0.02 | 0.82 | 0.20 | FR |

| And | 259.6 | 262.6 | 3.0 | 0.36 | 0.14 | 0.01 | 0.39 | 0.90 | 0.08 | FR |

| DDH22LU080 | 155.6 | 160.6 | 5.0 | 0.32 | 0.23 | 0.02 | 0.01 | 0.58 | 0.01 | FR |

| And | 186.6 | 195.3 | 8.7 | 0.92 | 0.47 | 0.06 | 0.01 | 1.46 | 0.46 | FR |

| Including | 186.5 | 188.5 | 2.0 | 2.89 | 1.03 | 0.16 | 0.03 | 4.11 | 1.68 | FR |

| And | 203.3 | 208.2 | 4.9 | 0.56 | 0.50 | 0.06 | 0.01 | 1.13 | 0.56 | FR |

| Including | 205.4 | 206.3 | 0.9 | 1.38 | 1.56 | 0.12 | 0.01 | 3.06 | 2.05 | FR |

| DDH22LU087 | 20.3 | 52.9 | 32.6 | 1.71 | 1.07 | 0.15 | 0.06 | 2.99 | NA | Ox/FR |

| Including | 41.9 | 52.9 | 11.0 | 2.62 | 1.36 | 0.18 | 0.08 | 4.24 | 0.27 | FR |

| And | 99.3 | 105.3 | 6.0 | 0.37 | 0.61 | 0.16 | 0.01 | 1.14 | 0.07 | FR |

| And | 130.4 | 134.6 | 4.2 | 0.44 | 0.32 | 0.07 | 0.03 | 0.87 | 0.25 | FR |

| And | 176.9 | 186.9 | 10.0 | 0.15 | 0.35 | 0.03 | 0.01 | 0.54 | 0.22 | FR |

| DDH22LU088 | 45.0 | 47.0 | 2.0 | 1.31 | 0.97 | 0.45 | 0.02 | 2.74 | 0.01 | FR |

| And | 109.6 | 115.6 | 6.0 | 1.21 | 0.86 | 0.12 | 0.04 | 2.24 | 0.08 | FR |

| And | 123.6 | 125.6 | 2.0 | 0.45 | 0.28 | 0.02 | 0.01 | 0.76 | 0.26 | FR |

| And | 140.7 | 142.7 | 2.0 | 0.40 | 0.34 | 0.01 | 0.01 | 0.75 | 0.16 | FR |

| And | 156.8 | 161.5 | 4.7 | 1.45 | 0.51 | 0.01 | 0.01 | 1.99 | 0.83 | FR |

| DDH22LU098 | 179.9 | 187.9 | 8.0 | 1.25 | 0.74 | 0.08 | 0.01 | 2.08 | 0.03 | FR |

| And | 197.9 | 211.0 | 13.1 | 0.41 | 0.28 | 0.06 | 0.01 | 0.75 | 0.13 | FR |

| And | 234.7 | 237.7 | 3.0 | 0.71 | 0.16 | 0.07 | 0.01 | 0.95 | 0.49 | FR |

Notes:

- All ‘From’, ‘To’ depths, and ‘Thicknesses’ are downhole.

- Given the orientation of the hole and the mineralization, the intercepts are estimated to be 85% to 100% of true thickness.

- Type: Ox = Oxide. LS = Low Sulphur. FR = Fresh Rock. Recovery methods and results will differ based on the type of mineralization.

- * = Bravo’s nickel grades are sulphide nickel, and do not include non-recoverable silicate nickel, unlike historic total nickel assays

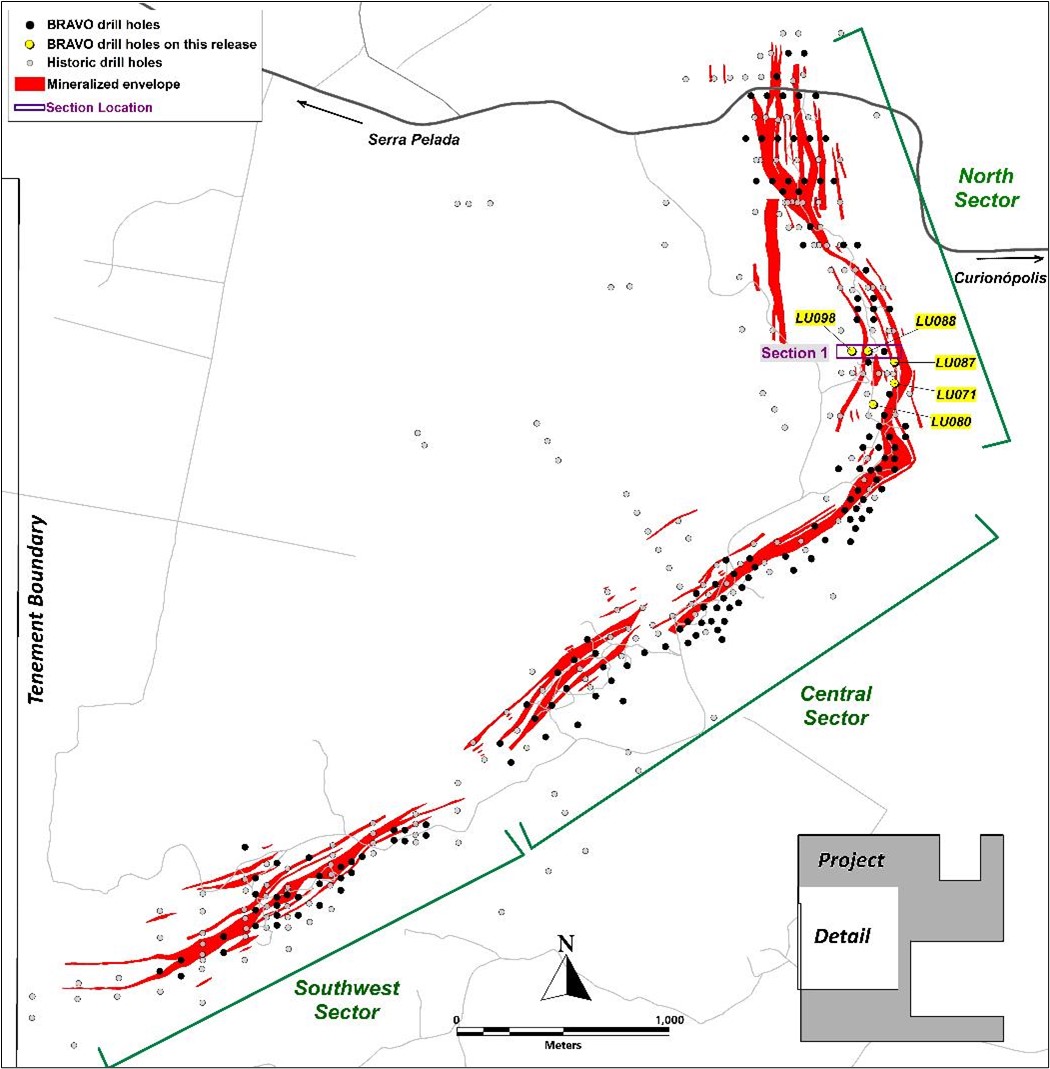

Figure 5: Location of Bravo Drilling Reported in this News Release

About Bravo Mining Corp.

Bravo is a Canada and Brazil-based mineral exploration and development company focused on advancing its Luanga PGM+Au+Ni Project in the world-class Carajás Mineral Province of Brazil.

The Luanga Project benefits from being in a location close to operating mines, with excellent access and proximity to existing infrastructure, including road, rail and clean and renewable hydro grid power. The project area was previously de-forested for agricultural grazing land. Bravo’s current Environmental, Social and Governance activities includes replanting trees in the project area, hiring and contracting locally, and ensuring protection of the environment during its exploration activities.

Technical Disclosure

Technical information in this news release has been reviewed and approved by Simon Mottram, F.AusIMM (Fellow Australia Institute of Mining and Metallurgy), President of Bravo Mining Corp. who serves as the Company’s “qualified person”, as defined in National Instrument 43-101 Standards of Disclosure for Mineral Projects (“NI 43-101”). Mr. Mottram has verified the technical data and opinions contained in this news release.

For further information about Bravo, please visit www.bravomining.com or contact:

Alex Penha

EVP Corporate Development

info@bravomining.com

Forward Looking Statements

This news release contains forward-looking information which is not comprised of historical facts. Forward-looking information is characterized by words such as “allow”, “pattern”, “evidence”, “potential”, “fast-track”, “focus”, “significant”, “prioritize”, “prospective”, “increasing presence”, “extension”, “suggest”, “seek”, “unlock”, “vector” variations of these words and other similar words, phrases, or statements that certain events or conditions “may”, “should”, “will” or “would” occur. This news release contains forward-looking information pertaining to the Company’s ongoing drill programs and the results thereof; the expected completion of geophysical surveys and the results of such surveys; the potential for mineralized extensions to depth at Luanga; the potential for nickel sulphide mineralization and the Company’s plans in respect thereof, and plans for completing a mineral resource estimate and the timing and results thereof. Forward-looking information involves risks, uncertainties and other factors that could cause actual events, results, and opportunities to differ materially from those expressed or implied by such forward-looking information. Factors that could cause actual results to differ materially from such forward-looking information include, but are not limited to, unexpected results from exploration programs, changes in the state of equity and debt markets, fluctuations in commodity prices, delays in obtaining required regulatory or governmental approvals, environmental risks, limitations on insurance coverage; and other risks and uncertainties involved in the mineral exploration and development industry. Forward-looking information in this news release is based on the opinions and assumptions of management considered reasonable as of the date hereof, including, but not limited to, the assumption that the assay results confirm that the interpreted mineralization contains significant values of nickel, PGMs and Au; that the mineralization remains open to depth, that grades are improving to depth, that final drill and assay results will be in line with management’s expectations; that activities will not be adversely disrupted or impeded by regulatory, political, community, economic, environmental and/or healthy and safety risks; that the Luanga Project will not be materially affected by potential supply chain disruptions; and general business and economic conditions will not change in a materially adverse manner. Although the Company believes that the assumptions and factors used in preparing the forward-looking information in this news release are reasonable, undue reliance should not be placed on such information. The Company disclaims any intention or obligation to update or revise any forward-looking information, other than as required by applicable securities laws.

Schedule 1: Drill Hole Collar Details

|

HOLE-ID |

Company | East (m) |

North (m) |

RL (m) |

Datum | Depth (m) |

Azimuth | Dip | Sector |

|---|---|---|---|---|---|---|---|---|---|

| DDH22LU071 | Bravo | 659999.92 | 9342125.03 | 278.85 | SIRGAS2000 UTM22S | 269.70 | 90.00 | -60.00 | North |

| DDH22LU080 | Bravo | 659900.26 | 9342025.03 | 254.09 | SIRGAS2000 UTM22S | 265.05 | 90.00 | -60.00 | North |

| DDH22LU087 | Bravo | 659999.97 | 9342225.03 | 274.29 | SIRGAS2000 UTM22S | 220.20 | 90.00 | -60.00 | North |

| DDH22LU088 | Bravo | 659874.86 | 9342274.98 | 239.38 | SIRGAS2000 UTM22S | 172.50 | 90.00 | -60.00 | North |

| DDH22LU098 | Bravo | 659800.16 | 9342275.03 | 237.42 | SIRGAS2000 UTM22S | 250.35 | 90.00 | -60.00 | North |

Schedule 2: Assay Methodologies and QAQC

Samples follow a chain of custody between collection, processing, and delivery to the ALS laboratory in Parauapebas, state of Pará, Brazil. The drill core is delivered to the core shack at Bravo’s Luanga site facilities and processed by geologists who insert certified reference materials, blanks, and duplicates into the sampling sequence. Drill core is half cut and placed in secured polyurethane bags, then in security-sealed sacks before being delivered directly from the Luanga site facilities to the Parauapebas ALS laboratory by Bravo staff. Additional information about the methodology can be found on the ALS global website (ALS) in the analytical guides.

Quality Assurance and Quality Control (“QAQC”) is maintained internally at the lab through rigorous use of internal certified reference materials, blanks, and duplicates. An additional QAQC program is administered by Bravo using certified reference materials, duplicate samples and blank samples that are blindly inserted into the sample batch. If a QAQC sample returns an unacceptable value an investigation into the results is triggered and when deemed necessary, the samples that were tested in the batch with the failed QAQC sample are re-tested.

Method

| Bravo ALS | |||||

|---|---|---|---|---|---|

| Preparation | Method | Method | Method | Method | Method |

| For All Elements | Pt, Pd, Au | Rh | Ni-Sulphide | Cu | Trace Elements |

| PREP-31DH | PGM-ICP27 | Rh-MS25 | Ni-ICP05 | OG-62 | ME-ICP61 |