Result is the thickest interval of continuous PGM+Au mineralization to date at Luanga

VANCOUVER, April 18, 2023 – Bravo Mining Corp. (TSX.V: BRVO, OTCQX: BRVMF), (“Bravo” or the “Company”) announced that it has received assay results from a further ten diamond infill drill holes (“DDH”) from its 100% owned Luanga palladium + platinum + rhodium + gold + nickel project (“Luanga” or “Luanga PGM+Au+Ni Project”), located in the Carajás Mineral Province, state of Pará, Brazil.

“New results from Luanga’s infill drilling completed in 2022 continue to encourage, comparing well with historic drilling on nearby drill sections, and to previously reported results from Bravo’s drilling on the same drill sections. DDH22LU100 from the North Sector is now the thickest known interval of continuous PGM+Au mineralization to date in the Luanga deposit. DDH22LU122 (North Sector) and DDH22LU123 (Central Sector) show continuing evidence of increasing levels of magmatic nickel (± copper) sulphide mineralization as drilling approaches the footwall ultramafic sequence,” said Luis Azevedo, Chairman and CEO of Bravo. “We look forward to advancing the Phase 2 program of extensional drilling, probing deeper into the Luanga deposit.”

Highlights Include:

- Assay results received from drilling at all three Sectors of the Luanga deposit continue to compare well with intercepts in historic drilling on nearby drill sections, both in tenor and mineralized thickness, and to previously reported results from Bravo drilling on the same drill sections.

- With a downhole thickness of 115.6m from surface, DDH22LU100 has intersected the thickest known interval of continuous mineralization to date within the Luanga

- A geophysical contractor is expected to start the HeliTEM (Helicopter Electromagnetic) survey over the entire Luanga project in May 2023. Surface micro-gravity and detailed ground magnetics are in progress.

- The surface trenching program will recommence in Q2.

| HOLE-ID | From (m) |

To (m) |

Thickness (m) |

Pd (g/t) |

Pt (g/t) |

Rh (g/t) |

Au (g/t) |

PGM + Au (g/t) |

Ni* (%) |

Cu (%) |

TYPE |

|---|---|---|---|---|---|---|---|---|---|---|---|

| DDH22LU100 | 0.0 | 115.6 | 115.6 | 0.53 | 0.84 | 0.01 | 0.00 | 1.38 | NA | NA | Ox/FR |

| DDH22LU105 | 52.4 | 59.4 | 7.0 | 1.57 | 0.82 | 0.12 | 0.32 | 2.65 | 0.01 | 0.05 | FR |

| DDH22LU115 | 31.0 | 67.0 | 36.0 | 0.93 | 0.93 | 0.15 | 0.03 | 2.04 | 0.18 | 0.02 | FR |

| DDH22LU119 | 63.9 | 86.9 | 23.0 | 0.88 | 0.32 | 0.04 | 0.02 | 1.25 | 0.13 | 0.01 | FR |

| DDH22LU121 | 44.7 | 53.7 | 9.0 | 1.29 | 0.75 | 0.15 | 0.08 | 2.27 | 0.12 | 001 | FR |

| DDH22LU122 | 0.0 | 12.2 | 12.2 | 1.52 | 1.09 | 0.25 | 0.12 | 2.99 | NA | NA | Ox |

| DDH22LU123 | 149.5 | 193.5 | 44.0 | 1.34 | 0.45 | 0.06 | 0.02 | 1.88 | 0.20 | 0.02 | FR |

| Including | 174.5 | 192.5 | 18.0 | 2.37 | 0.79 | 0.12 | 0.01 | 3.29 | 0.30 | 0.02 | FR |

| DDH22LU125 | 0.0 | 27.5 | 27.5 | 2.09 | 1.01 | 0.27 | 0.03 | 3.40 | NA | NA | Ox |

Notes:

- All ‘From’, ‘To’ depths, and ‘Thicknesses’ are downhole. ‘NA’ Not applicable for Oxide material.

- Given the orientation of the hole and the mineralization, the intercepts are estimated to be 80% to 95% of true thickness.

- Type: Ox = Oxide. LS = Low Sulphur. FR = Fresh Rock. Recovery methods and results will differ based on the type of mineralization.

- * Bravo’s nickel grades are sulphide nickel, and do not include non-recoverable silicate nickel, unlike historic total nickel assays

Luanga Drilling Assay Results Update

A total of 169 drill holes (34 in 2023) have been completed by Bravo to date, for 29,393 metres, including all 8 planned twin holes and all 8 metallurgical holes (not subject to routine assaying).

The Phase 1 drilling program has concluded, and the Phase 2 program has commenced (Figure 1).

Results have been reported for 119 Bravo drill holes to date. Excluding the metallurgical holes, results for42 Bravo drill holes are currently outstanding.

Figure 1: CEO, President, and VP Exploration at the first drill site of the Phase 2 Drilling Program.

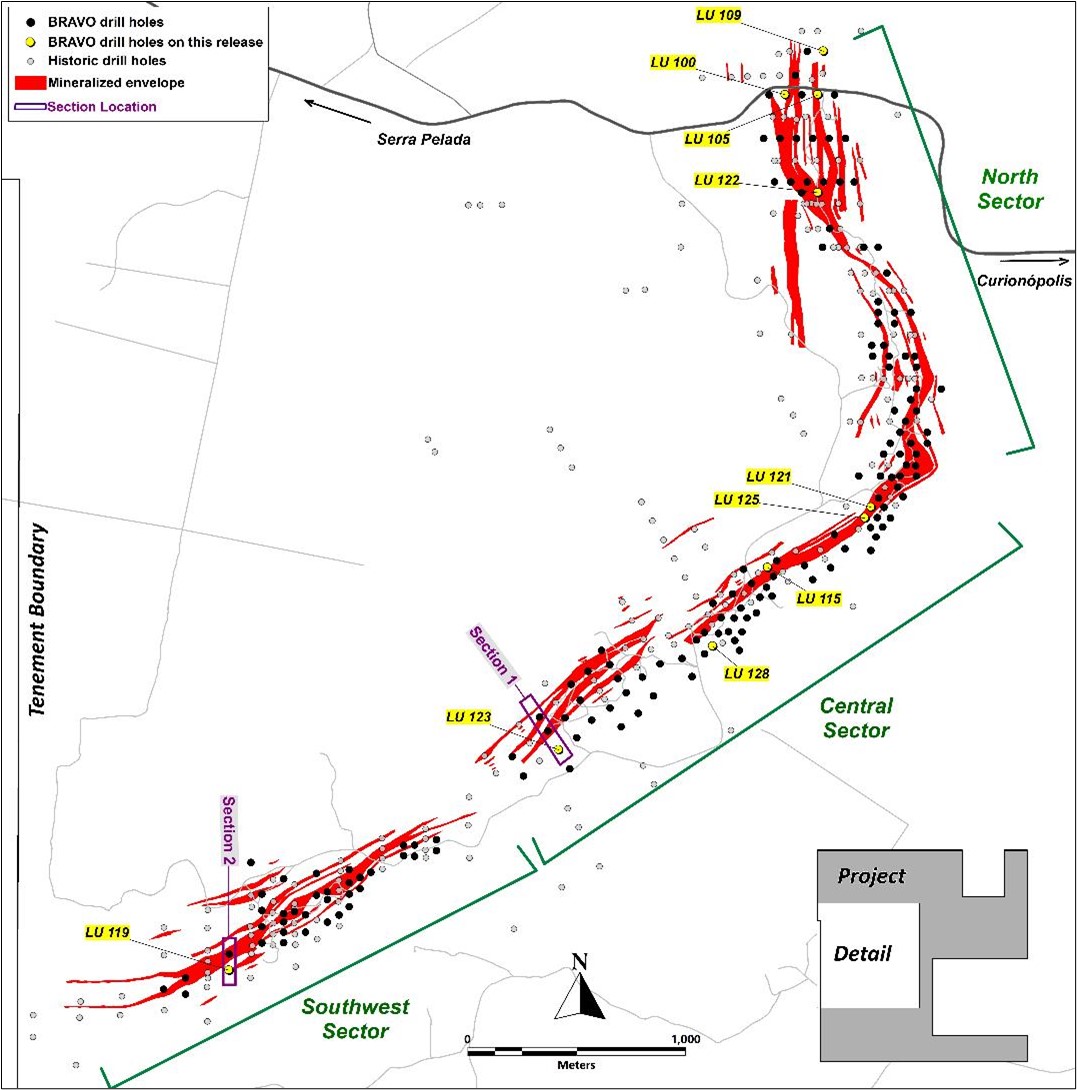

Drill results received from all three sectors at Luanga continue to compare well with intercepts in historic drilling on nearby drill sections and to previously reported results from Bravo drilling on the same drill sections (see Sections 1 and 2).

Drill results were received for four drill holes in the North Sector and continue to show multiple stacked zones of mineralization, as reported in previous news releases. DDH22LU100 is an exception to this, intersecting 115.6m of continuous mineralization from surface (the thickest mineralized interval intersected to date at Luanga), followed by narrow zones of seemingly unrelated copper (±gold) mineralization at depth. DDH22LU122 (North Sector) also returned narrow intervals of magmatic nickel/copper sulphide mineralization at depth, adding further evidence to the potential for magmatic nickel (± copper) sulphides at depth.

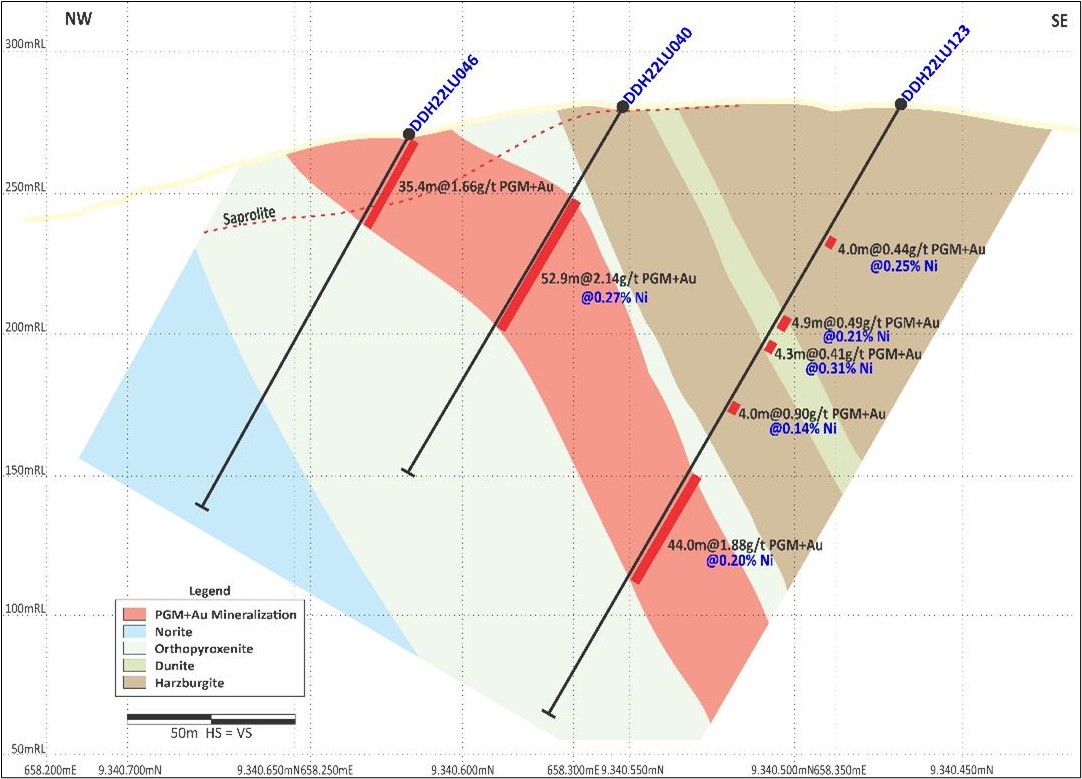

Drill results were received from five infill drill holes from the Central Sector and, as has been reported previously, mineralization is more typically dominated by one thicker zone of mineralization. Results in the Central Sector also continue to compare well with intercepts in historic drilling on neighbouring drill sections, and to shallower (up-dip) drilling (DDH22LU040 and 044, Figure 2 – Section 1) by Bravo on the same section.

Figure 2: Central Sector (Section 1 on Figure 5) – Ultramafic footwall sequence containing magmatic nickel sulphides.

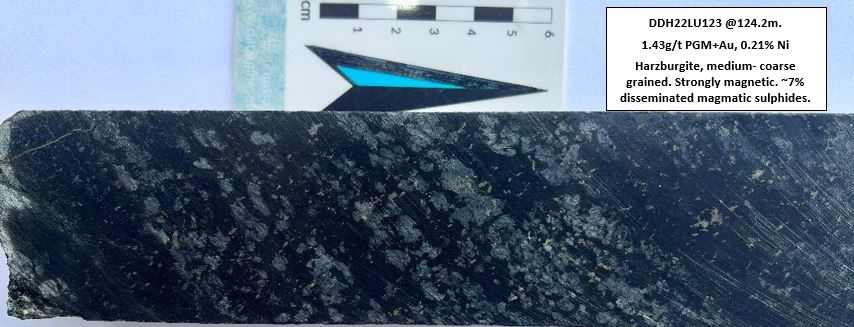

Figure 3: North Sector – DDH22LU123. Harzburgite from the ultramafic footwall sequence.

It is worth noting again that the Luanga intrusion has been turned on to its side. In the Southwest and Central Sectors Luanga has been rotated beyond vertical (I.E., is overturned), such that the basal (footwall) ultramafic sequence lies geographically above the known PGM+Au+Ni deposit. DDH22LU123 (Section 1) is a good example of Bravo’s drilling first needing to pass through ever-increasing thicknesses of the footwall ultramafic sequence to reach the interpreted down-dip extensions of the Luanga PGM+Au+Ni deposit. As shown on the section, zones of magmatic nickel sulphides continue to be present in the footwall ultramafic. Figure 3 (DDH22LU123) shows a typical example of Harzburgite ultramafic containing disseminated magmatic nickel sulphides.

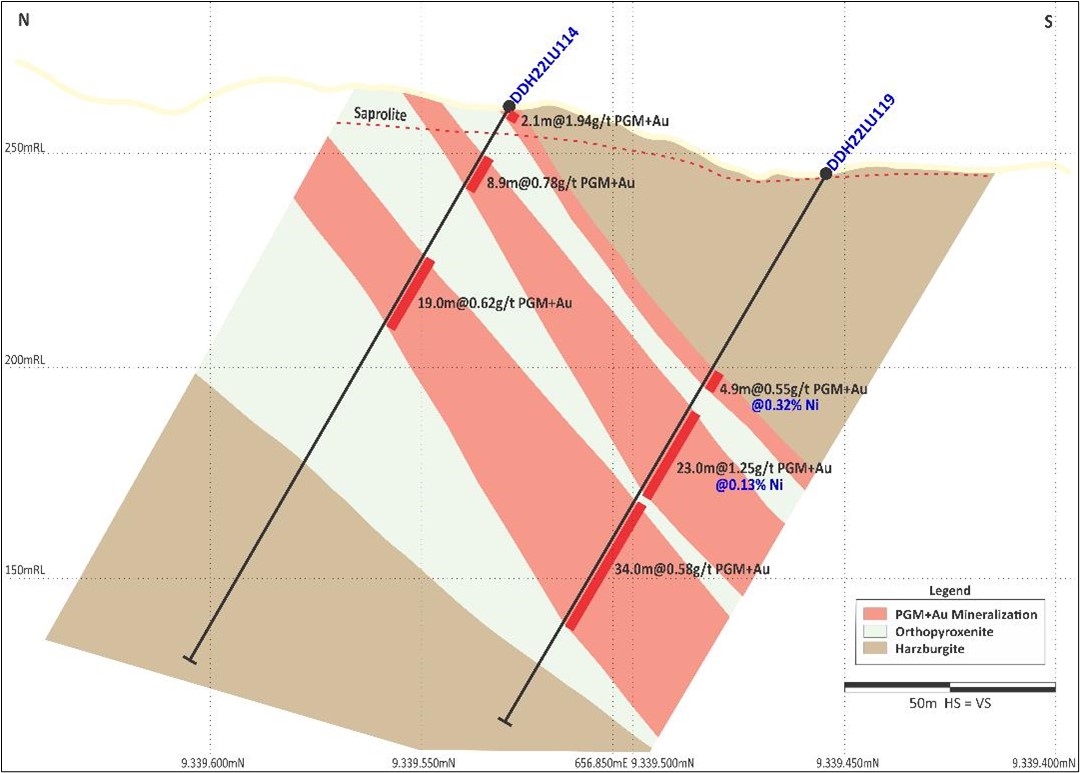

Figure 4: Southwest Sector (Section 2 on Figure 5) – Multiple zones of mineralization.

DDH22LU119 (Figure 4 – Section 2) was the only drill hole in this group of results from the Southwest Sector, with results comparing well with intercepts in historic drilling on neighbouring drill sections and comparing favourably to up-dip drilling (DDH22LU114) by Bravo on the same section.

Phase 2 Drill Program

The Phase 2 program has commenced, with 21,500 meters of drilling planned, focused on extensional drilling to depth (below the known mineralization) and exploration of new targets.

The extensional drilling seeks to follow the known Luanga PGM+Au+Ni mineralization down-dip while, at the same time, extending holes to depths sufficient to test the interface between the PGM host sequence and the ultramafic footwall sequence.

The Phase 2 program also includes a significant budget allocation for exploration, with an accelerated geophysical program aimed at generating magmatic nickel sulphide exploration targets and examining the entire Luanga project area, including areas outside the mineralized footprint identified to date.

A geophysical contractor is expected to start the HeliTEM (Helicopter Electromagnetic) survey over the entire Luanga project in May 2023. They are currently working on mobilization and permits.

Surface geophysical programs, micro-gravity and detailed ground magnetics, are now both in progress at Luanga.

Complete Table of Recent Intercepts

| HOLE-ID | From (m) |

To (m) |

Thickness (m) |

Pd (g/t) |

Pt (g/t) |

Rh (g/t) |

Au (g/t) |

PGM + Au (g/t) |

Ni* (%) |

Cu (%) |

TYPE |

|---|---|---|---|---|---|---|---|---|---|---|---|

| DDH22LU100 | 0.0 | 115.6 | 115.6 | 0.53 | 0.84 | 0.01 | 0.00 | 1.38 | NA | NA | Ox/FR/LS |

| And | 129.6 | 142.9 | 13.3 | 0.30 | 0.75 | 0.01 | 0.05 | 1.11 | 0.01 | 0.19 | FR |

| Including | 140.9 | 142.9 | 2.0 | 0.05 | 0.04 | 0.01 | 0.32 | 0.41 | 0.01 | 1.20 | FR |

| And | 147.9 | 150.9 | 3.0 | 0.00 | 0.01 | 0.00 | 0.05 | 0.07 | 0.01 | 0.35 | FR |

| DDH22LU105 | 0.0 | 2.0 | 2.0 | 0.52 | 0.21 | 0.03 | 0.05 | 0.81 | NA | NA | Ox |

| And | 33.4 | 37.4 | 4.0 | 0.57 | 0.16 | 0.00 | 0.01 | 0.75 | 0.01 | 0.01 | FR |

| And | 45.4 | 74.0 | 28.6 | 0.67 | 0.39 | 0.06 | 0.07 | 1.18 | 0.10 | 0.06 | FR |

| Including | 52.4 | 59.4 | 7.0 | 1.57 | 0.82 | 0.12 | 0.32 | 2.65 | 0.01 | 0.05 | FR |

| And | 79.5 | 85.5 | 6.0 | 0.50 | 0.27 | 0.03 | 0.01 | 0.82 | 0.02 | 0.03 | FR |

| DDH22LU109 | 0.0 | 3.7 | 3.7 | 0.42 | 0.45 | 0.02 | 0.01 | 0.90 | NA | NA | Ox |

| DDH22LU11511 | 0.0 | 3.1 | 3.1 | 0.62 | 0.40 | 0.02 | 0.06 | 1.10 | NA | NA | Ox |

| And | 31.0 | 67.0 | 36.0 | 0.93 | 0.93 | 0.15 | 0.03 | 2.04 | 0.18 | 0.02 | FR |

| DDH22LU119 | 53.0 | 57.9 | 4.9 | 0.19 | 0.06 | 0.07 | 0.23 | 0.55 | 0.32 | 0.02 | FR |

| And | 63.9 | 86.9 | 23.0 | 0.88 | 0.32 | 0.04 | 0.02 | 1.25 | 0.13 | 0.01 | FR |

| And | 88.9 | 122.9 | 34.0 | 0.35 | 0.21 | 0.01 | 001 | 0.58 | 0.04 | 0.01 | FR |

| DDH22LU121 | 0.0 | 4.0 | 4.0 | 0.52 | 0.50 | 0.10 | 0.01 | 1.13 | NA | NA | Ox |

| And | 28.2 | 31.2 | 3.0 | 1.08 | 0.73 | 0.18 | 0.01 | 1.99 | 0.01 | 0.01 | FR |

| And | 44.7 | 53.7 | 9.0 | 1.29 | 0.75 | 0.15 | 0.08 | 2.27 | 0.12 | 001 | FR |

| DDH22LU122 | 0.0 | 12.2 | 12.2 | 1.52 | 1.09 | 0.25 | 0.12 | 2.99 | NA | NA | Ox |

| And | 70.3 | 75.5 | 5.2 | 0.21 | 0.16 | 0.01 | 0.01 | 0.39 | 0.15 | 0.02 | FR |

| And | 80.5 | 87.5 | 7.0 | 0.36 | 0.38 | 0.05 | 0.05 | 0.84 | 0.08 | 0.04 | FR |

| And | 101.5 | 105.5 | 4.0 | 0.38 | 0.28 | 0.02 | 0.03 | 0.71 | 0.08 | 0.06 | FR |

| And | 118.2 | 125.2 | 7.0 | 0.36 | 0.17 | 0.02 | 0.12 | 0.68 | 0.09 | 0.04 | FR |

| And | 132.8 | 138.2 | 6.0 | 0.34 | 0.18 | 0.02 | 0.05 | 0.58 | 0.12 | 0.05 | FR |

| And | 150.3 | 152.5 | 2.2 | 0.10 | 0.03 | 1.11 | 0.00 | 1.24 | 0.55 | 0.19 | FR |

| And | 183.1 | 184.6 | 1.5 | 0.10 | 0.01 | 0.00 | 0.24 | 0.36 | 0.25 | 2.57 | FR |

| DDH22LU123 | 52.8 | 56.8 | 4.0 | 0.29 | 0.10 | 0.01 | 0.04 | 0.44 | 0.25 | 0.01 | FR |

| And | 85.5 | 90.4 | 4.9 | 0.28 | 0.10 | 0.07 | 0.04 | 0.49 | 0.21 | 0.17 | FR |

| And | 95.5 | 99.8 | 4.3 | 0.20 | 0.08 | 0.11 | 0.01 | 0.41 | 0.31 | 0.02 | FR |

| And | 120.8 | 124.8 | 4.0 | 0.58 | 0.21 | 0.01 | 0.11 | 0.90 | 0.14 | 0.07 | FR |

| And | 149.5 | 193.5 | 44.0 | 1.34 | 0.45 | 0.06 | 0.02 | 1.88 | 0.20 | 0.02 | FR |

| Including | 174.5 | 192.5 | 18.0 | 2.37 | 0.79 | 0.12 | 0.01 | 3.29 | 0.30 | 0.02 | FR |

| DDH22LU125 | 0.0 | 27.5 | 27.5 | 2.09 | 1.01 | 0.27 | 0.03 | 3.40 | NA | NA | Ox |

| And | 50.0 | 56.1 | 6.1 | 0.67 | 0.21 | 0.03 | 0.04 | 0.96 | 0.07 | 0.01 | FR |

| DDH22LU128 | 104.2 | 106.2 | 2.0 | 0.25 | 0.18 | 0.00 | 0.01 | 0.43 | 0.07 | 0.01 | FR |

Notes:

- All ‘From’, ‘To’ depths, and ‘Thicknesses’ are downhole. ‘NA’ Not applicable for Oxide material.

- Given the orientation of the hole and the mineralization, the intercepts are estimated to be 80% to 95% of true thickness.

- Type: Ox = Oxide. LS = Low Sulphur. FR = Fresh Rock. Recovery methods and results will differ based on the type of mineralization.

- * Bravo’s nickel grades are sulphide nickel, and do not include non-recoverable silicate nickel, unlike historic total nickel assays

Figure 5: Location of Bravo Drilling and Sections Reported in this News Release

About Bravo Mining Corp.

Bravo is a Canada and Brazil-based mineral exploration and development company focused on advancing its Luanga PGM+Au+Ni Project in the world-class Carajás Mineral Province of Brazil.

The Luanga Project benefits from being in a location close to operating mines, with excellent access and proximity to existing infrastructure, including road, rail and clean and renewable hydro grid power. The project area was previously de-forested for agricultural grazing land. Bravo’s current Environmental, Social and Governance activities includes replanting trees in the project area, hiring and contracting locally, and ensuring protection of the environment during its exploration activities.

Technical Disclosure

Technical information in this news release has been reviewed and approved by Simon Mottram, F.AusIMM (Fellow Australia Institute of Mining and Metallurgy), President of Bravo Mining Corp. who serves as the Company’s “qualified person” as defined in National Instrument 43-101 Standards of Disclosure for Mineral Projects (“NI 43-101”). Mr. Mottram has verified the technical data and opinions contained in this news release.

For further information about Bravo, please visit www.bravomining.com or contact:

Alex Penha

EVP Corporate Development

info@bravomining.com

Forward Looking Statements

This news release contains forward-looking information which is not comprised of historical facts. Forward-looking information is characterized by words such as “comparing well”, “seemingly unrelated”, “evidence”, “expected”, “better define”, “interpret”, “seek”, “potential”, “variants of these words and other similar words, phrases, or statements that certain events or conditions “will” or occur. This news release contains forward-looking information pertaining to the Company’s ongoing drill and trenching programs and the results thereof; the expected completion of geophysical surveys and the results of such surveys; the potential for the definition of new styles of mineralization (including magmatic Ni sulphides and copper) and the potential for extensions to depth; the interpretation that Ni grades increase in the basal portions of the intrusion and the Company’s plans in respect thereof. Forward-looking information involves risks, uncertainties and other factors that could cause actual events, results, and opportunities to differ materially from those expressed or implied by such forward-looking information. Factors that could cause actual results to differ materially from such forward-looking information include, but are not limited to, unexpected results from exploration programs, changes in the state of equity and debt markets, fluctuations in commodity prices, delays in obtaining required regulatory or governmental approvals, environmental risks, limitations on insurance coverage; and other risks and uncertainties involved in the mineral exploration and development industry. Forward-looking information in this news release is based on the opinions and assumptions of management considered reasonable as of the date hereof, including, but not limited to, the assumption that the assay results confirm that the interpreted mineralization contains significant values of nickel, PGMs and Au; that the mineralization remains open to depth, that Ni grades are improving to depth, that final drill and assay results will be in line with management’s expectations; that activities will not be adversely disrupted or impeded by regulatory, political, community, economic, environmental and/or healthy and safety risks; that the Luanga Project will not be materially affected by potential supply chain disruptions; and general business and economic conditions will not change in a materially adverse manner. Although the Company believes that the assumptions and factors used in preparing the forward-looking information in this news release are reasonable, undue reliance should not be placed on such information. The Company disclaims any intention or obligation to update or revise any forward-looking information, other than as required by applicable securities laws.

Schedule 1: Drill Hole Collar Details

| HOLE-ID | Company | East (m) | North (m) | RL (m) | Datum | Depth (m) | Azimuth | Dip | Sector |

|---|---|---|---|---|---|---|---|---|---|

| DDH22LU100 | Bravo | 659400.47 | 9343475.04 | 232.35 | SIRGAS2000 UTM22S | 165.35 | 90.00 | -60.00 | North |

| DDH22LU105 | Bravo | 659550.07 | 9343475.02 | 227.28 | SIRGAS2000 UTM22S | 150.30 | 90.00 | -60.00 | North |

| DDH22LU109 | Bravo | 659574.76 | 9343674.97 | 205.14 | SIRGAS2000 UTM22S | 150.00 | 90.00 | -60.00 | North |

| DDH22LU115 | Bravo | 659319.35 | 9341303.75 | 233.68 | SIRGAS2000 UTM22S | 150.40 | 330.00 | -60.00 | Central |

| DDH22LU119 | Bravo | 656850.00 | 9339455.08 | 245.38 | SIRGAS2000 UTM22S | 150.15 | 360.00 | -60.00 | Southwest |

| DDH22LU121 | Bravo | 659793.43 | 9341581.13 | 227.64 | SIRGAS2000 UTM22S | 150.35 | 330.00 | -60.00 | Central |

| DDH22LU122 | Bravo | 659550.06 | 9343024.97 | 275.12 | SIRGAS2000 UTM22S | 200.00 | 90.00 | -60.00 | North |

| DDH22LU123 | Bravo | 658361.10 | 9340466.59 | 281.30 | SIRGAS2000 UTM22S | 250.55 | 330.00 | -60.00 | Central |

| DDH22LU125 | Bravo | 659765.26 | 9341530.97 | 217.77 | SIRGAS2000 UTM22S | 149.85 | 330.00 | -60.00 | Central |

| DDH22LU128 | Bravo | 659067.09 | 9340943.14 | 245.67 | SIRGAS2000 UTM22S | 150.00 | 330.00 | -60.00 | Central |

Schedule 2: Assay Methodologies and QAQC

Samples follow a chain of custody between collection, processing, and delivery to the SGS laboratory in Parauapebas, state of Pará, Brazil. The drill core is delivered to the core shack at Bravo’s Luanga site facilities and processed by geologists who insert certified reference materials, blanks, and duplicates into the sampling sequence. Drill core is half cut and placed in secured polyurethane bags, then in security-sealed sacks before being delivered directly from the Luanga site facilities to the Parauapebas SGS laboratory by Bravo staff. Additional information about the methodology can be found on the SGS Geosol website (SGS) in their analytical guides. Information regarding preparation and analysis of historic drill core is also presented in the table below, where the information is known.

Quality Assurance and Quality Control (“QAQC”) is maintained internally at the lab through rigorous use of internal certified reference materials, blanks, and duplicates. An additional QAQC program is administered by Bravo using certified reference materials, duplicate samples and blank samples that are blindly inserted into the sample batch. If a QAQC sample returns an unacceptable value an investigation into the results is triggered and when deemed necessary, the samples that were tested in the batch with the failed QAQC sample are re-tested.

| Bravo SGS Geosol | ||||

|---|---|---|---|---|

| Preparation | Method | Method | Method | Method |

| For All Elements | Pt, Pd, Au | Rh | Sulphide Ni, Cu | Trace Elements |

| PRP102_E (95% at 150#) | FAI515 | FAA35J | ICP04B | ICP40B |