Trenching highlights include 146.8m at 2.05g/t PGM+Au, including 50.0m at 4.18g/t PGM+Au Metallurgical drill core highlights include 110.0m at 2.23g/t PGM+Au, including 35.0m at 3.51g/t PGM+Au, 0.16% Ni

VANCOUVER, May 08, 2023 – Bravo Mining Corp. (TSX.V: BRVO, OTCQX: BRVMF), (“Bravo” or the “Company”) announced that it has received assay results from five trenches and four previously unsampled large diameter (“ZW”) historical metallurgical drill holes, all located in the Southwest sector of its 100% owned Luanga palladium + platinum + rhodium + gold + nickel project (“Luanga” or “Luanga PGM+Au+Ni Project”), located in the Carajás Mineral Province, state of Pará, Brazil.

“Initial trenching shows potential for increased thickness and supergene enrichment, warranting an expanded trenching program at Luanga”, said Luis Azevedo, Chairman and CEO of Bravo. “In addition, the receipt of assay results from the large diameter metallurgical drill core that had not been sampled by the previous owner has provided valuable localized grade and geological information and, more importantly, tonnes of mineralized material, both oxide and fresh rock, that is immediately available for Phase 2 metallurgical program and/or later pilot scale test work.”

Highlights Include:

- Trenching trialed in the Southwest Sector successfully defined thicker zones of mineralization at surface in comparison to nearest neighbour drill holes below the trench, while assay results indicate grade enrichment in most cases.

- Historical drill core received at site includes large diameter ZW metallurgical core (165mm) drilled in the Southwest Sector that had not been previously sampled. Assay results from channel sampling of this core are as good or better than nearby drill holes, supporting Bravo’s interpretation of geology and mineralization. The core is now ready for use in the Phase 2 metallurgical program.

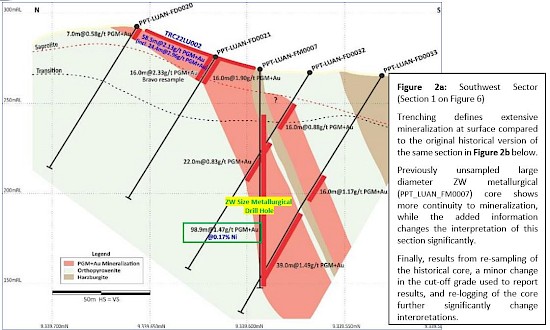

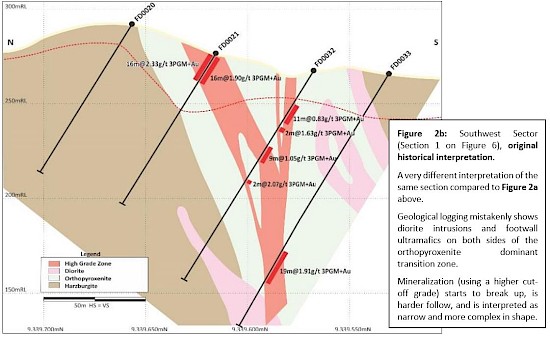

- The combinations of trenching, assay results from the ZW metallurgical core re-sampling and re-logging have improved interpreted mineralization in these areas (see Figures 2a and 2b).

| TRENCH-ID | From (m) |

To (m) |

Thickness (m) |

Pd (g/t) |

Pt (g/t) |

Rh (g/t) |

Au (g/t) | PGM + Au (g/t) |

TYPE |

| TRC22LU002 | 24.1 | 82.6 | 58.5 | 1.46 | 0.54 | 0.09 | 0.03 | 2.13 | Ox |

| TRC22LU003 | 20.6 | 167.4 | 146.8 | 1.36 | 0.59 | 0.07 | 0.03 | 2.05 | Ox |

| Including | 41.3 | 91.3 | 50.0 | 2.90 | 1.06 | 0.15 | 0.06 | 4.18 | Ox |

| TRC22LU004 | 0.0 | 81.1 | 81.1 | 0.98 | 0.42 | 0.05 | 0.04 | 1.48 | Ox |

| TRC22LU005 | 28.0 | 57.9 | 29.9 | 1.25 | 0.46 | 007 | 0.12 | 1.90 | Ox |

| TRC22LU006 | 0.0 | 39.3 | 39.3 | 1.10 | 0.42 | 0.08 | 0.11 | 1.70 | Ox |

Notes: All ‘From’, ‘To’ and ‘Thickness’ measurements are true measurements. Type: Ox = Oxide.

The recovery of PGM+Au from saprolitic material is being tested as part of the ongoing metallurgical program.

| HOLE-ID | From (m) |

To (m) |

Thickness (m) |

Pd (g/t) |

Pt (g/t) |

Rh (g/t) |

Au (g/t) | PGM + Au (g/t) |

Ni** (%) | Cu (%) | TYPE |

| *FM-0004 | 0.0 | 110.0 | 110.0 | 1.39 | 0.64 | 0.08 | 0.12 | 2.23 | NA | NA | Ox/FR |

| Including | 68.7 | 103.7 | 35.0 | 2.25 | 1.01 | 0.15 | 0.11 | 3.51 | 0.16 | 0.02 | FR |

| *FM-0007 | 26.1 | 125.0 | 98.9 | 1.02 | 0.38 | 0.05 | 0.03 | 1.47 | 0.17 | 0.02 | FR |

Notes: All ‘From’, ‘To’ depths, and ‘Thicknesses’ are downhole. ‘NA’ Not applicable for Oxide material. * Prefix “PPT-LUAN- “and are historical ZW core.

Given the orientation of the trenches at surface, the intercepts are estimated to be 95% to 150% of true thickness.

Type: Ox = Oxide. LS = Low Sulphur. FR = Fresh Rock. Recovery methods and results will differ based on the type of mineralization.

** Bravo’s nickel grades are sulphide nickel, and do not include non-recoverable silicate nickel, unlike historic total nickel assays

Luanga Trenching Program

A trial program testing the effectiveness of trenching commenced at Luanga’s Southwest Sector (Figure 1) in 2022. Trenching across the strike of the outcrop/sub-crop aimed to accurately map mineralization at surface to enable better interpretation for the planned Mineral Resource Estimate (“MRE”), and to reduce the distance/spacing between assay data points in preparation for later MRE classification (i.e., Indicated/Inferred). Trenching also provides detailed outcrop mapping, supporting interpretation of the near surface at Luanga.

The trenching program has also highlighted the increase in mineralized thickness intersected in shallow drillholes nearby. Assay results from trenching (Figures 2, 3, & 4) clearly show that mineralization in the saprolite zone (above the base of oxidation) increases in thickness, common in tropical weathering profiles. Figure 7 shows mineralized thicknesses in plan. In addition, the PGM grades in the trench samples compare favourably to the high-grade intersections in nearby down dip drillholes (Figures 2 & 3). This further suggests supergene enrichment in the saprolite zone.

Figure 1: Trenching in the Southwest Sector.

Luanga Metallurgical Drill Core

Historical ZW core (165mm diameter core from a 192mm diameter drill hole) (Figure 5) has been received by Bravo for four holes in the Southwest Sector (Figure 6). This core was initially intended for bulk sampling metallurgical test work by the previous owner but was not previously sampled. Bravo has relogged the core, located and verified the locations of these drill holes, and received assay results from its channel sampling of the core. Sampling procedures followed the same methodology (cutting core to both regolith and lithological contacts) and QAQC procedures used on the Company’s own drill core. These historical ZW holes were drilled to cover a range of mineralization locations across the Southwest Sector, as shown in Figure 6. The core is to be used in the Phase 2 metallurgical program.

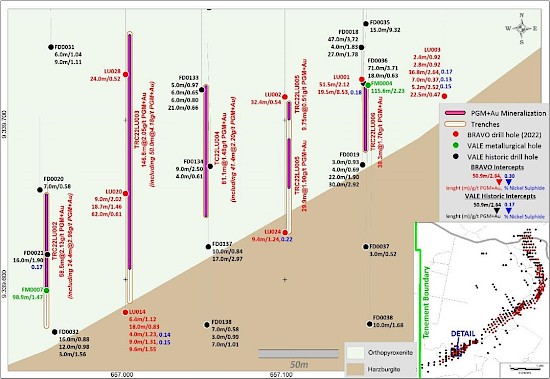

Two versions of the same drill section are shown below (Figure 2a & 2b). Figure 2a is the current version, with a trench form drill holes PPT-LUAN-FD0020 to PPT-LUAN-FM0004, with the extended zone of mineralization and high grades at surface. Trench assay grades are also superior to assay grades in nearest neighbour drilling below the trench, supportive of supergene enrichment. Figure 2b shows the original historical interpretation of the same section, without the benefit of new data. See notes on the sections for details of key changes.

Figure 2a and 2b: Southwest Sector (Section 1 on Figure 8) – Trenching defines mineralization at surface. ZW core assays improve continuity.

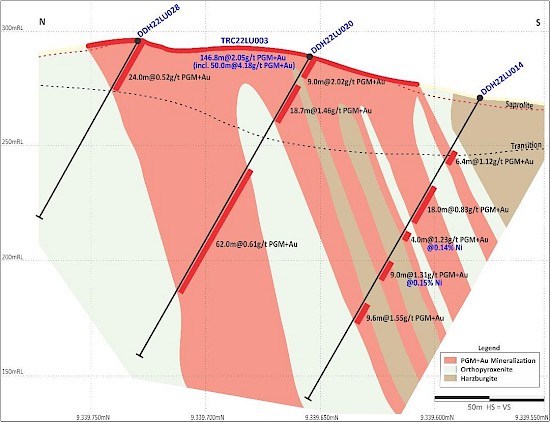

Figure 3 shows a longer trench excavated to completely cover the potential thickness of mineralization at surface, where both the southern and northern limits to mineralization had not been defined by drilling. Trenching now provides a factual basis for interpretation, showing that mineralization merges in the saprolite zone to produce a continuous 146m thick layer of mineralized interval at surface. Again, assay grades encountered in trenching are higher than assay grades in nearest drill holes below the trench, supporting the existence of supergene enrichment.

Figure 3: Southwest Sector (Section 2 on Figure 7) – Trenching testing both the northern and southern limits of mineralization at surface.

Whereas the saprolite zone is relatively thin (ranging from <2m on the ridge line, to 25m away from the ridge), given Luanga’s 8.1km of strike, the presence of similar saprolite layer +/- secondary enrichment could result in the definition of a significant volume of saprolite zone/oxide mineralization in a future MRE.

Trenching, performed to a high quality, replaces the requirement for the many shallow drill holes that would be needed to achieve the same result for the coming Phase 1 MRE. The same sampling, assay laboratory procedures and QAQC protocols as applied to drill core sampling are applied to trench samples.

Given the encouraging results from trenching to date, trenching is planned to continue in 2023 along the entire 8.1km strike length of the Luanga deposit.

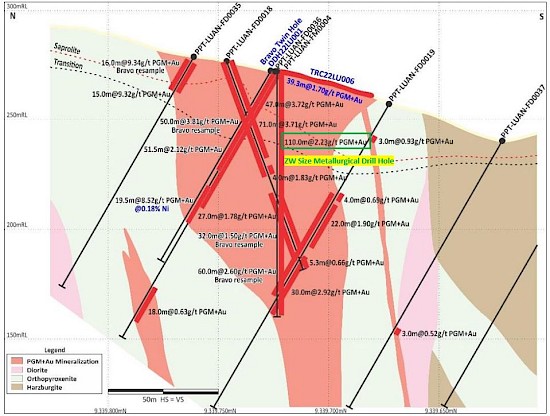

Figure 4 shows how trenching to the south of metallurgical drill hole PPT-LUAN-FM0004 has defined the southern limit to mineralization at surface. Previously this was interpreted more conservatively. Trench data provides a factual basis for interpretation, with mineralization extending far closer to drill hole PPT-LUAN-FD0019. Sampling of ZW core metallurgical drill hole PPT-LUAN-FM0004 again shows the excellent continuity of mineralization.

Figure 4: Southwest Sector (Section 3 on Figure 7) – Trenching from PPT-LUAN-FD0036 to 0019 testing the southern limit of mineralization.

Figure 5: Geological logging of ZW size metallurgical drill core compared to regular NQ2 core.

Figure 6: Southwest Sector – Plan view of trenches completed in the Southwest Sector.

Figure 6 shows a surface plan of the 5 trenches completed to date in the Southwest Sector. Thick magenta-coloured stripes show the thickness of mineralization at surface in the trenches.

Luanga Drilling Status

A total of 175 drill holes (40 in 2023) have been completed by Bravo to date, for 31,510 metres, including all 8 planned twin holes and all 8 metallurgical holes (not subject to routine assaying). These 8 metallurgical holes are in addition to the four ZW historical holes received from Vale.

The Phase 2 drilling program is currently in progress.

Results have been reported for 119 Bravo drill holes to date. Excluding the metallurgical holes, results for 48 Bravo drill holes are currently outstanding.

Complete Table of Recent Intercepts - Trenching

| TRENCH-ID | From (m) |

To (m) |

Thickness (m) |

Pd (g/t) |

Pt (g/t) |

Rh (g/t) |

Au (g/t) | PGM + Au (g/t) |

TYPE |

| TRC22LU002 | 24.1 | 82.6 | 58.5 | 1.46 | 0.54 | 0.09 | 0.03 | 2.13 | Ox |

| Including | 56.2 | 80.6 | 24.4 | 2.05 | 0.75 | 0.13 | 0.02 | 2.96 | Ox |

| TRC22LU003 | 20.6 | 167.4 | 146.8 | 1.36 | 0.59 | 0.07 | 0.03 | 2.05 | Ox |

| Including | 41.3 | 91.3 | 50.0 | 2.90 | 1.06 | 0.15 | 0.06 | 4.18 | Ox |

| TRC22LU004 | 0.0 | 81.1 | 81.1 | 0.98 | 0.42 | 0.05 | 0.04 | 1.48 | Ox |

| Including | 0.0 | 41.4 | 41.4 | 1.50 | 0.55 | 0.09 | 0.06 | 2.20 | Ox |

| TRC22LU005 | 28.0 | 57.9 | 29.9 | 1.25 | 0.46 | 0.07 | 0.12 | 1.90 | Ox |

| And | 71.1 | 80.9 | 9.8 | 0.27 | 0.20 | 0.02 | 0.03 | 0.51 | Ox |

| TRC22LU006 | 0.0 | 39.3 | 39.3 | 1.10 | 0.42 | 0.08 | 0.11 | 1.70 | Ox |

| Including | 30.0 | 36.0 | 6.0 | 2.29 | 0.98 | 0.17 | 0.28 | 3.71 | Ox |

Notes: All ‘From’, ‘To’ and ‘Thickness’ measurements are true measurements. Type: Ox = Oxide.

The recovery of PGM+Au from saprolitic material is being tested as part of the ongoing metallurgical program.

Complete Table of Recent Intercepts – Historical Metallurgical Drill Core

| HOLE-ID | From (m) |

To (m) |

Thickness (m) |

Pd (g/t) |

Pt (g/t) |

Rh (g/t) |

Au (g/t) | PGM + Au (g/t) |

Ni** (%) | Cu (%) | TYPE |

| *FM-0004 | 0.0 | 110.0 | 110.0 | 1.39 | 0.64 | 0.08 | 0.12 | 2.23 | NA | NA | Ox/FR |

| Including | 68.7 | 103.7 | 35.0 | 2.25 | 1.01 | 0.15 | 0.11 | 3.51 | 0.16 | 0.02 | FR |

| *FM-0005 | 37.5 | 42.5 | 5.0 | 0.42 | 0.15 | 0.03 | 0.02 | 0.62 | 0.26 | 0.01 | FR |

| And | 70.5 | 80.5 | 10.0 | 0.82 | 0.34 | 0.06 | 0.03 | 1.26 | 0.05 | 0.01 | FR |

| *FM-0006 | 25.7 | 44.5 | 18.8 | 0.75 | 0.44 | 0.07 | 0.12 | 1.37 | 0.18 | 0.02 | FR |

| And | 59.0 | 74.8 | 15.8 | 0.85 | 0.43 | 0.06 | 0.10 | 1.45 | 0.17 | 0.02 | FR |

| *FM-0007 | 26.1 | 125.0 | 98.9 | 1.02 | 0.38 | 0.05 | 0.03 | 1.47 | 0.17 | 0.02 | FR |

Notes: All ‘From’, ‘To’ depths, and ‘Thicknesses’ are downhole. ‘NA’ Not applicable for Oxide material. * Prefix “PPT-LUAN- “and are historical ZW core.

Given the orientation of the trenches at surface, the intercepts are estimated to be 95% to 150% of true thickness.

Type: Ox = Oxide. LS = Low Sulphur. FR = Fresh Rock. Recovery methods and results will differ based on the type of mineralization.

** Bravo’s nickel grades are sulphide nickel, and do not include non-recoverable silicate nickel, unlike historic total nickel assays

Figure 7: Location of Bravo Trenches and Sections Reported in this News Release

About Bravo Mining Corp.

Bravo is a Canada and Brazil-based mineral exploration and development company focused on advancing its Luanga PGM+Au+Ni Project in the world-class Carajás Mineral Province of Brazil.

The Luanga Project benefits from being in a location close to operating mines, with excellent access and proximity to existing infrastructure, including road, rail and clean and renewable hydro grid power. The project area was previously de-forested for agricultural grazing land. Bravo’s current Environmental, Social and Governance activities includes replanting trees in the project area, hiring and contracting locally, and ensuring protection of the environment during its exploration activities.

Technical Disclosure

Technical information in this news release has been reviewed and approved by Simon Mottram, F.AusIMM (Fellow Australia Institute of Mining and Metallurgy), President of Bravo Mining Corp. who serves as the Company’s “qualified person” as defined in National Instrument 43-101 Standards of Disclosure for Mineral Projects (“NI 43-101”). Mr. Mottram has verified the technical data and opinions contained in this news release.

For further information about Bravo, please visit www.bravomining.com or contact:

Alex Penha

EVP Corporate Development

info@bravomining.com

Forward Looking Statements

This news release contains forward-looking information which is not comprised of historical facts. Forward-looking information is characterized by words such as “potential”, “upgrade”, “enrichment”, “bonus”, “successful”, “significant impact”, or variants of these words and other similar words, phrases, or statements that certain events or conditions “will” occur. This news release contains forward-looking information pertaining to the Company’s ongoing trenching program, the impact of large diameter historical metallurgical drill core on future mineral resource estimates; the interpretation of the results of trench data, including that the mineralization thickens in the saprolite and is locally supergene enriched and the impact on mineral resource estimates thereof; the potential that similar thickening and supergene enrichment may be present along the entire strike length of the Luanga deposit and the impact on mineral resource estimates thereof; the potential future economics of the saprolite material, including the recoverability of PGMs and Au therefrom; and the results of planned additional trenching and drilling. Forward-looking information involves risks, uncertainties and other factors that could cause actual events, results, and opportunities to differ materially from those expressed or implied by such forward-looking information. Factors that could cause actual results to differ materially from such forward-looking information include, but are not limited to, unexpected results from exploration programs, changes in the state of equity and debt markets, fluctuations in commodity prices, delays in obtaining required regulatory or governmental approvals, environmental risks, limitations on insurance coverage; and other risks and uncertainties involved in the mineral exploration and development industry. Forward-looking information in this news release is based on the opinions and assumptions of management considered reasonable as of the date hereof, including, but not limited to, the assumption that the assay results confirm that the interpreted mineralization contains significant values of PGMs and Au; that the mineralization remains open to depth, that assay results will be in line with management’s expectations; that activities will not be adversely disrupted or impeded by regulatory, political, community, economic, environmental and/or healthy and safety risks; that the Luanga Project will not be materially affected by potential supply chain disruptions; and general business and economic conditions will not change in a materially adverse manner. Although the Company believes that the assumptions and factors used in preparing the forward-looking information in this news release are reasonable, undue reliance should not be placed on such information. The Company disclaims any intention or obligation to update or revise any forward-looking information, other than as required by applicable securities laws.

Schedule 1: Trench Location Details

| HOLE-ID | Company | East (m) | North (m) | RL (m) | Datum | Length (m) |

Az. | Dip | Sector |

| TRC22LU002 | Bravo | 656950.35 | 9339571.90 | 263.62 | SIRGAS2000 UTM22S | 82.61 | 360.00 | 0.00 | Southwest |

| TRC22LU003 | Bravo | 657002.64 | 9339587.51 | 269.28 | SIRGAS2000 UTM22S | 168.43 | 360.00 | 0.00 | Southwest |

| TRC22LU004 | Bravo | 657050.51 | 9339641.18 | 270.65 | SIRGAS2000 UTM22S | 81.08 | 360.00 | 0.00 | Southwest |

| TRC22LU005 | Bravo | 657102.38 | 9339631.05 | 258.05 | SIRGAS2000 UTM22S | 80.85 | 360.00 | 0.00 | Southwest |

| TRC22LU006 | Bravo | 657150.52 | 9339682.18 | 259.35 | SIRGAS2000 UTM22S | 39.30 | 360.00 | 0.00 | Southwest |

| PPT-LUAN-FM0004 | Vale | 657150.57 | 9339724.66 | 277.00 | SIRGAS2000 UTM22S | 110.00 | 0.00 | -90.00 | Southwest |

| PPT-LUAN-FM0005 | Vale | 657750.57 | 9340094.66 | 269.00 | SIRGAS2000 UTM22S | 90.35 | 0.00 | -90.00 | Southwest |

| PPT-LUAN-FM0006 | Vale | 657350.57 | 9339856.66 | 267.00 | SIRGAS2000 UTM22S | 87.80 | 0.00 | -90.00 | Southwest |

| PPT-LUAN-FM0007 | Vale | 656950.57 | 9339593.66 | 281.88 | SIRGAS2000 UTM22S | 125.00 | 0.00 | -90.00 | Southwest |

Schedule 2: Assay Methodologies and QAQC

Samples follow a chain of custody between collection, processing, and delivery to the SGS laboratory in Parauapebas, state of Pará, Brazil. Samples are delivered to the core shack at Bravo’s Luanga site facilities and processed by geologists who insert certified reference materials, blanks, and duplicates into the sampling sequence. Samples are placed in secured polyurethane bags, then in security-sealed sacks before being delivered directly from the Luanga site facilities to the Parauapebas SGS laboratory by Bravo staff. Additional information about the methodology can be found on the SGS Geosol website (SGS) in their analytical guides.

Quality Assurance and Quality Control (“QAQC”) is maintained internally at the lab through rigorous use of internal certified reference materials, blanks, and duplicates. An additional QAQC program is administered by Bravo using certified reference materials, duplicate samples and blank samples that are blindly inserted into the sample batch. If a QAQC sample returns an unacceptable value an investigation into the results is triggered and when deemed necessary, the samples that were tested in the batch with the failed QAQC sample are re-tested.

| Bravo SGS Geosol | ||||

| Preparation | Method | Method | Method | Method |

| For All Elements | Pt, Pd, Au | Rh | Sulphide Ni, Cu, Co | Trace Elements |

| PRP102_E (95% at 150#) | FAI515 | FAA35J | ICP04B | ICP40B |